We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

In manufacturing, keeping your workplace clean and free from contaminants isn’t just a priority – it's mandatory. Your product’s quality painting or coating can be compromised by dust and particulate matter during the production process.

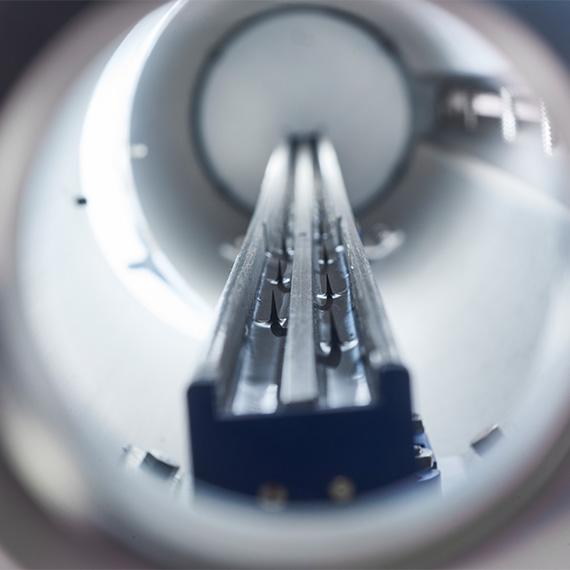

Air Force 1 Feather Dusters offer a cutting-edge solution that combines the precision of feather rollers or bars along with the power of Air Knives or direct-drive blowers. AF1’s innovative approach ensures that your products are not only free from particulate and dust, but it paves the way for unmatched quality and consistency.

AF1 Feather Dusters are advanced dust and particulate removal tools that combine feather rollers or feather bars, air knives, and blower systems to remove contaminants from product surfaces gently and effectively.

AF1 Feather Duster Systems deliver thorough cleaning and particulate removal through a precise, multi-step process:

Feather Rollers or Bars: The process begins with gentle feather rollers or bars that softly brush the surface of the product. These are designed to lift and remove loose dust and particulate without damaging the surface. The feather rollers or bars are ideal for delicate surfaces where harsher cleaning methods might cause abrasion or wear.

Air Knives: Following the feather rollers or bars, the system uses strategically placed Air Knives to blow off any remaining dust and particulate. The Air Knives generate a powerful, high-velocity air stream that effectively dislodges particles from the surface. This step ensures that even the most stubborn contaminants are removed, leaving the product clean and ready for the next stage of manufacturing. In highly contaminated processes, sometimes Air Knives are also used prior to the feather rollers or bars as well.

Direct-Drive Blowers: The Air Knives are powered by direct-drive blowers, which deliver a consistent and reliable air supply. Unlike traditional blower systems, direct-drive blowers are more efficient, providing greater airflow with less energy consumption. This makes the AF1 Feather Duster System not only effective but also energy-efficient, reducing operational costs over time.

Gentle and Safe for Delicate Surfaces: Our patented Feather Duster Systems ensure that even the most delicate surfaces are cleaned without any risk of damage. This makes it ideal for the electronic, automotive, and packaging industries where maintaining a surface’s cleanliness is critical.

Effective Dust and Particulate Removal: An optimized combination of AF1 feather rollers or bars, Air Knives, and direct blowers ensures that all dust and particulate is thoroughly removed. This results in much cleaner products that meet the highest quality standards.

Enhanced Product Quality: By removing contaminants, AF1 Feather Duster Systems help improve the overall quality of your products. This leads to fewer defects, less waste, and increased customer satisfaction.

Energy Efficiency: Our direct drive blowers are designed to be energy-efficient, providing powerful air flow all while consuming less energy than other tools and methods. This reduces the environmental impact of your operations whilst saving money on energy costs.

Ease of Integration: Our systems are designed for easy integration into existing production lines, meaning we can minimize possible production disruption and downtime. Its modular design allows for seamless incorporation into your workplace, making sure you have a smooth transition and maximizing the benefits.

AF1 Feather Dusters are versatile and can be applied to a wide range of industries and applications:

Automotive Manufacturing: Ensures that commonly painted or coated vehicle components, such as body panels, bumpers, headlight assemblies, etc., are free of dust before proceeding with the painting or assembly process.

Electronics: Removes dust and particulate from delicate electronic components to prevent possible malfunctions and ensure product reliability.

Packaging: Perfect for cleaning packaging materials, such as films and containers, to maximize hygiene and prevent contamination of the final product.

Printing: Ensures that printing surfaces, such as paper and plastics, are completely free from dust – eliminating the risk of print defects and compromised quality.

Pharmaceuticals: Effectively removes particulate from packaging and production equipment to make sure you’re adhering to stringent hygiene and quality standards.

By choosing AF1 Feather Duster Systems, you’re investing in a long-term solution that’s proven to enhance your product quality while also improving your manufacturing efficiency. You may even save on operational costs, too.

Our systems utilize innovative designs along with versatility and energy efficiency, making it the ideal choice for any manufacturing environment where dust and particulate removal is essential.

Whether you’re producing high-end electronics, precise automotive parts, or even sensitive pharmaceutical products, AF1 Feather Dusters provide the reliability and performance you need to maintain a productive manufacturing process.

Several industries can benefit from using an AF1 Feather Duster: our systems can be applied to the automotive sector, pharmaceutical, and even in the diverse realm of electronics. Anywhere you need to clean a surface without the risk of damage, an AF1 Feather Duster can be beneficial.

AF1 Feather Dusters can be utilized across various surfaces, such as delicate materials such as electronics, automotive parts, packaging films, and printing surfaces.

The Air Knives create a high velocity air stream that not only effectively removes dust and particulate, but also prevents them from settling back onto the surface. They also often incorporate anti-static bars to assist in the blow off process.