Harness the power of air with AF1 Air Knives. Our cutting-edge technology delivers a precise, high-velocity curtain of air for a wide range of industrial applications.

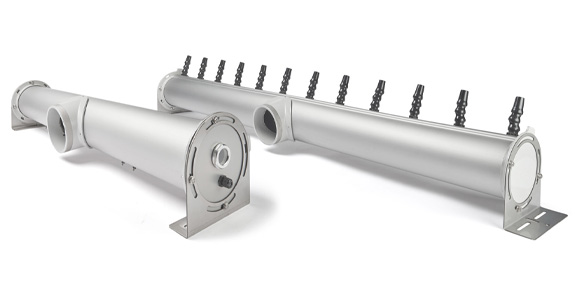

Air Force 1’s Air Knives provide the precision and power you need to optimize your cleaning, drying, and cooling applications. Engineered for durability and built to last, our Air Knives are constructed from high-quality anodized aluminum or stainless steel to resist corrosion and withstand demanding environments. Custom materials are also available.

Combined with our Direct Drive Blowers – designed and sized specifically for our Air Knives and Air Cannon Nozzles – you get a complete, high-performance system that's ready to tackle your toughest production challenges.

Air Knives are nozzles with long, narrow slots that shape the airflow produced by a blower to produce a smooth, laminar airflow. This means the air moves in parallel layers, minimizing turbulence and producing a consistent, forceful air stream and energy efficient.

Air, supplied by a blower, enters the Air Knife system and is accelerated through a narrowing chamber for maximum impact. The resulting high-velocity sheet of air is then released through the adjustable orifice, allowing precise delivery to your target surface, whether it's a moving product or a stationary component.

Length: From compact 6" models for small components to 240" versions for wide webs and air seals, we'll engineer the precise length you need. Custom lengths beyond our standard range are also available.

Profile: Choose from standard or custom profiles to match the exact contours of your product or process, ensuring optimal airflow coverage and efficiency.

Material: Select hard anodized aluminum for the majority of standard applications or stainless steel for corrosive environments, ensuring durability and longevity.

Orifice Size: Fine-tune the air velocity and volume by adjusting the slot orifice size, giving you precise control over the airflow characteristics.

Mounting Options: Simplify installation and integration with our variety of mounting options, including flanges, brackets, and clamps.

For specialized applications, we offer additional features to customize your Air Knife system further:

Neutralize static charges for sensitive electronics and other static-prone materials.

Ensure uniform airflow distribution across the entire length of longer Air Knives.

Protect your Air Knife from harsh environments with specialized coatings that enhance corrosion resistance.

Blow Off

Blast away dust, debris, and contaminants from your bottles and cans, and other products, components, and machinery to clean the surface for painting, coating, packaging, or assembly. The high-velocity air stream acts like a powerful, non-contact brush, efficiently dislodging and removing unwanted particles and liquids.

Drying

Slash drying times after washing, rinsing, painting, or coating, boosting your production efficiency and minimizing downtime. The laminar airflow of the Air Knife speeds the evaporation of moisture from surfaces.

Cooling

Quickly and safely cool heated materials to prevent personnel injuries, packaging concerns, warping, deformation, and other heat-related damage. Air Knives can also help to maintain precise temperature ranges for sensitive materials or processes that require specific temperature conditions.

Static Control

Neutralize static charges to protect sensitive electronics, prevent dust attraction, and improve overall safety in your facility. When equipped with ionization devices, our Air Knives generates positive and negative ions that neutralize static charges on surfaces. This prevents dust attraction, neutralizes static charges on circuit boards, components, or packaging materials, and eliminates static that can cause misfeeds or jams in printing presses. Static bars can be mounted inside our Air Knives to help prevent them being damaged and for long service.

Plasma cutting tables

Welding stations

Paint booths

Down draft tables

No two manufacturing processes are exactly alike. Air Force 1's blow off systems provide the flexibility and customization you need to optimize your production line, your way.

Our team of engineers will dive deep into your specific requirements and work collaboratively with you to design a custom solution that seamlessly fits your production equipment, environment, and requirements.

No matter your industry or application, AF1 has the expertise to create a custom blow off solution that delivers unparalleled performance and value.

30+ Year Track Record

30+ Year Track Record

With over three decades of innovation, Air Force 1 is the proven leader in custom blow off solutions that solve real manufacturing challenges. Our track record speaks for itself – countless successful installations and satisfied customers across the globe.

Custom-Engineered Solutions

Custom-Engineered Solutions

Your production line is one-of-a-kind, and your blow off solution should be too. We thrive on tackling your challenges head-on with custom systems that integrate with your workflow and address your needs.

In-House Manufacturing

In-House Manufacturing

Your investment in a blow off system is an investment in long-term quality. Our in-house manufacturing excellence and rigorous quality control guarantees your AF1 system won't let you down.

Global Reach & Local Support

Global Reach & Local Support

We bring your custom solution to your doorstep. From international shipping and export documentation to on-site installation support, AF1 gets your blow off system up and running quickly, no matter your location.

An AF1 Air Knife is a custom-designed air delivery device that precisely and evenly distributes air flow for maximum performance and efficiency. Combined with our direct drive blowers, our Air Knives are a low-maintenance and reliable solution for your blow-off needs.

AF1 Air Knives can be used for stripping liquids, removing static, eliminating dust and particulate, drying e-coatings, and more. Our knives are used in the automotive and bottling industries, but can be custom-tailored for nearly any use.

At AF1, we engineer and manufacture custom sizes of Air Knives to match the requirements of your particular application. We can design an Air Knife blow-off system for nearly any product, from car bodies to small components. Contact us for a free consultation.

AF1 Air Knives are made from extruded aircraft-grade hard anodized aluminum, including the body, end flanges, and all stainless steel mounting hardware. We also offer stainless steel-based knives for food industry use and particularly corrosive environments.

AF1 Air Knives are blower-driven and custom-designed for your unique application. It is capable of producing over 20,000 fpm, but exact speeds and volumes are determined by the system designed for your needs, to maintain overall efficiency.

Air Knives provide a gentle, non-contact cleaning and drying solution, minimizing the risk of damage to delicate surfaces, such as with brushes or scrapers. They deliver a uniform and precise sheet of air for consistent results across large areas.

Our team of engineers will assess your application requirements, considering factors such as material type, surface area, desired air velocity, and environmental conditions, to recommend the most suitable Air Knife.

Yes, our Air Knives can be customized in terms of length, profile, material, orifice size, supply feeds, and mounting options to match your specific application needs perfectly.