Air Force 1 (AF1) designs and builds custom static control solutions, including Air Knives equipped with specialized static bars, to address your manufacturing challenges. These static bars emit a carefully balanced stream of positive and negative ions, efficiently neutralizing static charges on the surface of parts and contaminating dust particles.

Our anti-static systems use anti-static bars along with our blower generated nozzles to deliver static neutralizing process air.

When manufacturing involves sensitive components, static discharge can be disastrous. Our Static Control Systems protect your products and prevent costly damage. The ionized air from our specialized air knives guarantees that intricate parts, remain free from static during the vital processes of cleaning, assembly, and drying processes. Anti-static blowers effectively clean these sensitive parts.

Static causes plastic sheets, films, and other materials to cling to each other and/or attract dust. AF1’s specialized Air Knives, along with integrated static bars, help ensure that these materials are static-free and can also prevent potential issues such as jamming and maintaining the product’s quality.

Static electricity can cause paper jams and misfeeds in the printing process. Our static control systems neutralize static charges on the surface of paper and other substrates, ensuring uninterrupted and smooth operations.

During the packaging process, static electricity attracts dust and other contaminants, potentially impacting the appearance and quality of the final product. AF1 Air Knives eliminate static to ensure clean and proper packaging.

When producing medical devices, maintaining a static-free environment is essential to prevent contamination and ensure the safety and integrity of the final product. AF1’s static control systems offer the necessary static neutralization.

Improved Product Quality: Our anti-static Air Knife systems work by neutralizing static charges, thereby preventing dust attraction as well as contamination.

Enhanced Safety: Our products minimize the risk of static discharge, which can sometimes cause sparks and ignite flammable materials or damage the product. This helps ensure you as well as your workers are safe.

Increased Efficiency: Static-free materials are less likely to cling together or to equipment, reducing jams and ensuring smooth operation.

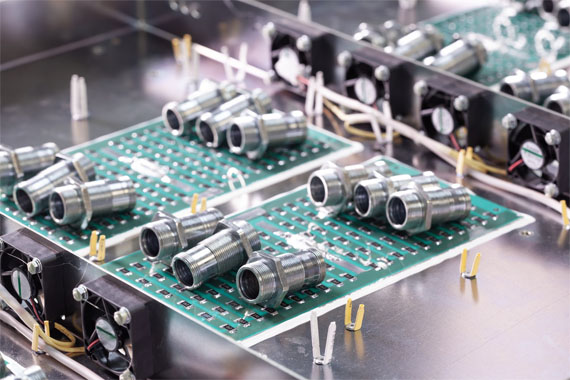

Protection of Sensitive Components: Especially in electronics and medical device manufacturing, our static control Air Knife systems protect sensitive components from damage due to static discharge.

High-Voltage Power Supply: Our static bars operate with a high-voltage power supply, ensuring effective ion generation. Static bar remote monitoring of condition is also available.

Customizable Air Knives: The Air Knives can be customized to fit specific applications and configurations, providing optimal coverage and static neutralization.

Durable Construction: Built to withstand industrial environments, our static bars and air knives are robust and reliable. Note that AF1 can install the static bars inside the Air Knives to protect the bars from physical damage, dirt or paint buildup, and allow the nozzles to be that much closer to product surface for higher and more efficient impact.

Easy Integration: AF1 Static Control Systems can be easily integrated into existing production lines, providing immediate benefits.

Regular Maintenance: To ensure consistent performance, a static bar should be kept clean - regular monitoring is recommended.

Monitoring: Optional static remote monitoring systems can be added to continuously measure and manage static levels, ensuring optimal control.

AF1’s systems utilize high voltage static bars that emit both positive and negative ions. These ions are carried by the airflow from our customized Air Knives, which effectively neutralizes static charges on surfaces and in the air, preventing static-related problems such as dust attraction and material cling.

AF1 Static Control Systems are versatile and can be used in numerous industries, including:

Automotive paintlines

Bottling and can lines

Electronics Manufacturing

Plastic and Film Handling

Printing Industry

Packaging

Medical Device Manufacturing

The key benefits include:

Improved Product Quality:

Prevents dust attraction as well as potential contamination.

Enhanced Safety:

Reduces the risk of static discharge and possible ignition of flammable materials.

Increased Efficiency:

Prevents materials from sticking, reducing jams and possible downtime.

Protection of Sensitive Components:

Our patented systems safeguard delicate electronics and medical devices from static damage.

Yes, AF1’s static control systems are specifically designed for your unique needs, including making for easy integration into existing production lines.

AF1’s Air Knife systems can be adjusted to suit several applications. This allows us to provide optimal coverage and static neutralization.

Our static bars operate with a power supply, which is included with the system. Detailed specifications and requirements will be provided based on your specific setup. We can also include continuous and remote monitoring with certain power supplies so an end user knows what condition the bars are in.

We offer optional static monitoring systems that can be integrated with our static control solutions. These monitoring systems continuously measure and manage static levels and levels of ion output, ensuring optimal static control.

Absolutely! Our team is available to provide technical support, from initial setup and integration to ongoing maintenance and troubleshooting. We are committed to ensuring your system operates efficiently and effectively.