We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

Every successful manufacturing process starts with the right components.

Air Force 1 manufactures a range of patented air cannon nozzles, custom-manufactured air knives, and reliable direct drive blowers engineered to deliver results. These components form the building blocks of a custom solution designed to solve your production challenges and take your operation to new heights.

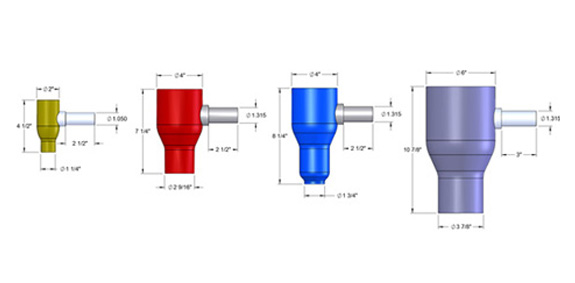

AF1’s patented Air Cannon Nozzles deliver high-velocity, targeted air blasts that often exceed 10,000 fpm (feet per minute) at a distance of 18 inches or more (depending on system requirements). These blow-off nozzles are ideal for removing stubborn dust and debris, steel shot, rapid heating, drying, or cooling, controlling static electricity, and other applications requiring powerful, focused air blasts.

Material: Spun aluminum construction – durable, lightweight, and easy to integrate.

Size: Standard 2", 4", 6" and 8” diameter blow off nozzles, or custom sizes to meet your needs.

Outlet Configuration: Single or multiple outlets for targeted or widespread air delivery.

Accelerator insert maximizes range, air velocity and impact for superior performance.

Machined handle with pipe clamps ensures secure mounting and precise positioning.

Mounting solutions are customized to seamlessly integrate with your existing equipment.

Optional coatings protect against abrasion and chemical exposure.

Hard anodized finish provides a professional look and additional corrosion resistance.

AF1 Air Knives deliver a continuous, laminar sheet of high-velocity air along the full blade length, providing unparalleled precision for cleaning, drying, cooling, and static control in your manufacturing processes. Durable hard anodized aluminum or stainless-steel construction ensures reliable performance in even the most demanding conditions.

Material: Hard anodized aluminum or stainless steel for durability and corrosion resistance.

Length: 6" to 240" common range, but custom lengths available upon request.

Orifice size is adjustable to fine-tune air velocity, impact and volume.

Standard or custom profiles to match your product or process contours.

Mounting options include flanges, brackets, and clamps for easy installation.

AF1’s corrosion-resistant Direct Drive Industrial Blowers are the powerhouse behind our custom solutions. Designed and manufactured in-house, these blowers provide exceptional efficiency and unmatched reliability, delivering consistent performance and longevity.

Materials: Choose from corrosion-resistant metals, high-temperature plastics, and other specialized options. Non-sparking designs for the Class 1, Div 1 (Hazardous Location) applications are available.

Configurations: Select standard configurations or request custom designs to fit your space and mounting needs.

Customizable to meet your specific needs, including airflow performance, materials, configurations, and integrated solutions.

Integrate with automated controls, filtration systems, air knives, and air cannon nozzles for a complete blow off solution.

Direct connection between the motor shaft and impeller is common and eliminates energy losses associated with belts and pulleys, maximizing power delivery to your process, as well as minimizing maintenance and break downs.

Virtually maintenance-free – our industrial blowers commonly have no belts or pulleys to replace, reducing downtime and maintenance costs.

Heavy-duty materials and robust construction ensure reliable operation in harsh industrial environments.

Precisely engineered impellers deliver consistent airflow for optimal results.

Across industries, leading manufacturers rely on Air Force 1 components to solve challenges in their production processes. Our team is ready to collaborate with you to develop a custom system that meets your needs.

Drying parts after pretreatment and PTED/E-Coating

Removing static charges and dirt from car parts during manufacturing processes

Cooling components after ovens and quenching

Preventing cross-contamination using air showers

Cleaning bottles and cans before filling

Drying food products and packaging after pasteurizing and washing

Removing dust from packaging

Maintaining sterile environments

Drying vials and ampules

Preventing cross-contamination using air showers

Removing contaminants from circuit boards

Cooling components during production

Controlling static to protect sensitive electronics

Cleaning and drying aerospace components

Cooling parts after testing

Removing debris from aircraft machining

30+ Year Track Record

30+ Year Track Record

With over three decades of innovation, Air Force 1 is the proven leader in custom blow off solutions that solve real manufacturing challenges. Our track record speaks for itself – countless successful installations and satisfied customers across the globe.

Custom-Engineered Solutions

Custom-Engineered Solutions

Your production line is one-of-a-kind, and your blow off solution should be too. We thrive on tackling your challenges head-on with custom systems that integrate with your workflow and address your needs.

In-House Manufacturing

In-House Manufacturing

Your investment in a blow off system is an investment in long-term quality. Our in-house manufacturing excellence and rigorous quality control guarantees your AF1 system won't let you down.

Global Reach & Local Support

Global Reach & Local Support

We bring your custom solution to your doorstep. From international shipping and export documentation to on-site installation support, AF1 gets your blow off system up and running quickly, no matter your location.

Air cannon nozzles deliver targeted, high-velocity blasts (over 10,000 fpm at 18+ inches) for stubborn debris or contoured parts, while air knives provide a continuous laminar sheet for uniform drying/cooling on flat surfaces like conveyor belts. Choose nozzles for focused impact and knives for broad coverage—both outperform compressed air in efficiency.

Start with your application (e.g., drying after coating, static removal), part size/contours, and required velocity/range—standard nozzle sizes are 2-8 inches, air knives 6-240 inches with adjustable orifices. AF1 engineers custom blower sizing to match, ensuring optimal airflow without excess energy use.

Yes, direct-drive blowers eliminate belt losses for lower operating costs and maintenance, powering nozzles/knives consistently in harsh environments. They're ideal for drying, cooling, or cleaning in automotive/food/pharma, with non-sparking options for hazardous areas—far more reliable than compressed air.

Custom mounting includes machined handles, pipe clamps, flanges, brackets for nozzles/knives, plus seamless blower integration with controls/filtration. Hard anodized aluminum/stainless steel ensures durability; optional coatings handle abrasion/chemicals—designed for quick installs with minimal downtime.

Virtually maintenance-free: no belts/pulleys means less downtime; check for debris in knives/nozzles and ensure equal inlet pressure on longer units (>24 inches). Robust construction lasts in industrial settings—contact AF1 for remote troubleshooting or upgrades.