That threaded fitting still has water in it. You can see droplets sitting in the blind hole even after your blow off system ran. The recessed area behind the mounting flange is still wet. Your standard air knives swept across the flat surfaces just fine, but they can't reach into the geometry where moisture hides.

This creates problems downstream. Paint won't adhere properly over trapped moisture. Coatings develop pinholes where water evaporates during curing.

Parts that looked dry during inspection fail quality checks later when hidden moisture causes corrosion or contamination.

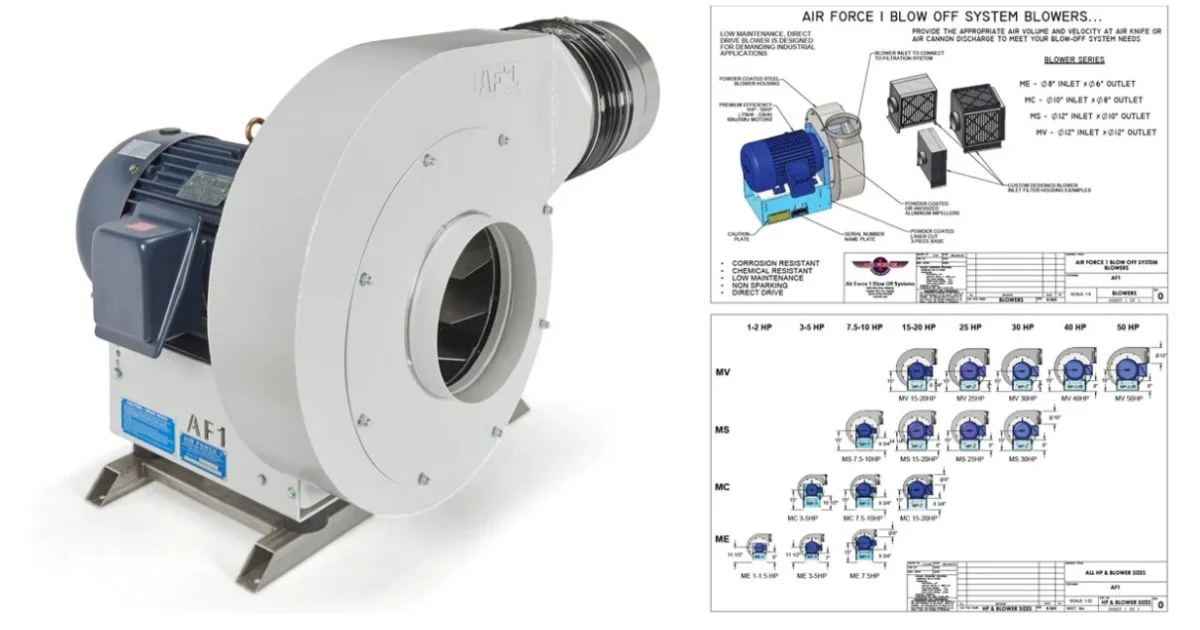

Most facilities try to solve this by using compressed air nozzles positioned closer or operated at higher pressure. That approach wastes energy while still missing the problem areas. Air cannon nozzles deliver focused, high-velocity air that reaches into recesses, threads, and complex features where standard systems can't operate effectively.

Why Standard Blow Off Can't Reach Everything

Air knives excel at covering large, relatively flat surfaces. They create uniform airflow across wide areas, making them perfect for drying bottles, panels, or conveyed parts with simple geometries. But that same uniform coverage becomes a limitation when parts have depth.

The air sheet from a knife flows across surfaces rather than penetrating into them. Recessed areas, blind holes, and undercuts sit in the shadow of the main airflow. Water trapped in these spaces doesn't reach the required velocity for removal.

Increasing air pressure doesn't solve the geometry problem. Higher pressure from an air knife still flows across the surface. You're using more energy without improving results for drying hard-to-reach areas.

Compressed air nozzles seem like they'd work better since they're smaller and more targeted. They do penetrate better than air knives, but they create their own problems. Compressed air systems account for 10-30% of electricity consumption in industrial facilities. The air quality often contains oil and moisture that can contaminate your parts. Most facilities discover they're spending more on compressed air waste than they realize.

Where Moisture Hides in Complex Parts

Automotive suspension components have mounting points, bolt holes, and recessed areas where water collects. A quick pass under air knives might dry the visible surfaces, but moisture remains in the geometry. That water causes rust spots that show up weeks later or interferes with powder coating adhesion.

Machined parts with threaded holes present consistent problems. Threads create spiral channels that trap water through surface tension. Standard blowoff passes over the threads without forcing air through them. The part looks dry on inspection, but carries moisture that causes problems during assembly or operation.

Castings and fabricated assemblies often have internal passages, weld seams, and irregular surfaces. Water finds its way into every low spot and stays there unless specifically targeted.

Medical device components with small features and tight tolerances can't afford any residual moisture. Contamination from trapped water creates serious quality and safety issues.

Electronics housings have mounting posts, snap features, and recessed areas for connectors. Water in these spots can cause short circuits, corrosion, or interference with assembly processes.

How Air Cannons Reach Problem Areas

Air cannon nozzles generate focused streams rather than broad sheets. This concentrated airflow penetrates into recessed areas rather than flowing over them. The targeted approach delivers adequate velocity directly to where moisture hides.

Multiple outlet configurations address different geometries. Some applications need several focused streams, hitting different features simultaneously. Others work better with single concentrated blasts that can be precisely aimed.

Accelerator inserts increase both velocity and effective range without requiring higher system pressure, helping dislodge water from areas where surface tension would otherwise hold it in place.

Getting air into recessed features requires outlets that can access holes, channels, and complex geometries. Focused delivery means you're putting air only where you need it, rather than wasting flow on already-dry surfaces.

Static control integration matters when dealing with complex geometries. Recessed areas often carry static charges that attract dust and particles after drying. Built-in ionization neutralizes these charges while the air removes moisture, preventing contamination from returning to freshly dried surfaces.

Application Strategies That Actually Work

Positioning matters more with air cannons than with air knives. You're targeting specific features rather than covering broad areas. Walk through your current process and identify exactly which features stay wet after standard blow off.

Part orientation during drying significantly affects results. Features that face downward or sideways may need different air cannon positioning than upward-facing areas. Gravity works with you when water can drain after being dislodged. Trapped pockets that can't drain need sustained airflow to remove moisture completely.

Sequential drying sometimes makes sense for parts with both large surfaces and complex features. Air knives handle broad areas efficiently, while air cannons target problem spots. This combination uses each technology where it works best, rather than forcing a single approach to handle everything.

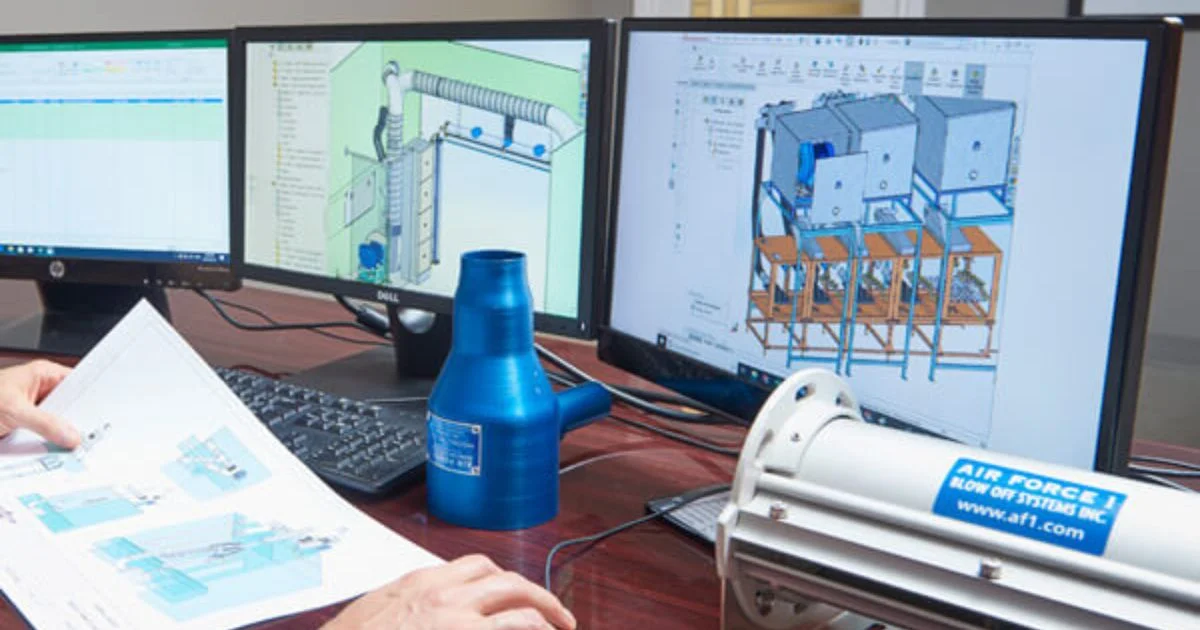

Integration with existing production lines determines practical implementation. Systems can be designed for manual operation, where parts are hand-loaded, or for fully automated, in-line operation, where parts move continuously. The key is removing moisture without creating production bottlenecks.

When Compressed Air Makes Sense

Some applications genuinely work better with compressed air despite the energy cost. Very short cycle times, where blow off happens for just seconds per hour, favor compressed air over maintaining a continuous blower system. The question is whether your application fits that pattern.

Facilities with excess compressed air capacity already in place might use it for blow off without adding new equipment. This makes sense only if the compressed air isn't needed elsewhere, and the energy waste doesn't offset the capital savings. Most plants discover their compressed air capacity isn't actually excess once they account for all the inefficient uses.

Portable applications that require blow off at multiple locations without fixed infrastructure sometimes justify the use of compressed air. The flexibility of moving hoses around can outweigh the energy penalty if usage is truly intermittent. Fixed production lines rarely fit this scenario.

The honest assessment: most facilities using compressed air for blow off would benefit from switching to blower-driven systems. The energy savings typically justify equipment investment within months.

Measuring Whether Your Current Approach Works

Parts that fail quality checks downstream often trace back to inadequate drying. Paint defects, coating failures, or corrosion issues that develop after passing initial inspection suggest trapped moisture. Tracking these failures by part geometry reveals patterns.

Production slowdowns caused by drying bottlenecks are reflected in cycle-time data. When your line waits for parts to dry, or when you're rejecting parts that aren't dry enough, the drying system has become your constraint. Quantifying how often this happens establishes the business case for better equipment.

Energy costs for compressed air blow off can be calculated once you know operating hours and system pressure. Research on manufacturing energy use shows that compressed air often ranks among the most expensive utilities in industrial facilities. Most facilities are surprised by the actual cost when they run the numbers.

Maintenance time spent on compressed air systems adds up through leak repairs, filter changes, and pressure checks. Direct drive blowers require less attention by eliminating belt maintenance entirely. The time savings matter as much as the energy savings.

Why This Matters Beyond Just Getting Parts Dry

Coating failures that trace back to moisture contamination cost more than just the rework. You've invested in surface preparation, coating materials, curing time, and handling before discovering the problem. Complete drying before coating prevents throwing money away on work that won't last.

Assembly problems caused by corroded threads, stuck fasteners, or contaminated surfaces create cascading delays. When parts that looked fine during drying cause issues during assembly, you're troubleshooting symptoms rather than addressing the root cause. Proper industrial part drying eliminates these downstream surprises.

Product warranties suffer when moisture-related failures appear in the field. Parts that passed all inspections but carried hidden moisture can fail during service. The cost of warranty claims exceeds the cost of proper drying equipment by orders of magnitude.

Facilities that consistently deliver dry, contamination-free parts build reputations that support premium pricing. Those fighting recurring moisture problems compete on price because they can't compete on quality.

Getting Started with Better Drying

Document exactly where moisture remains on your parts after current blow off. Take parts through your existing process, then identify specific features that stay wet.

Calculate what inadequate drying costs through rework, scrap, warranty claims, and production delays. These numbers justify investment in proper equipment and help prioritize which parts need attention first.

At Air Force 1, we design blow off systems using air cannons positioned specifically for your part geometries. Our engineering team analyzes where moisture hides on your parts and develops configurations that reach those areas effectively.

Air cannons solve drying problems that standard systems miss. When parts have complexity that traps moisture, targeted air delivery removes it completely. The result is consistent quality without the energy waste and maintenance demands of compressed air alternatives.

Ready to eliminate moisture problems in complex part geometries? Contact our team to discuss how custom air cannon solutions can solve your specific drying challenges.