Belt replacements keep showing up in maintenance logs. Every few weeks, another failure on the blow off system. Someone tracks down the right size, pulls a technician off other work, swaps it out, and checks alignment.

The pattern becomes clear fast. Belt-driven blowers don't just need occasional parts. They demand constant attention, unplanned downtime, and emergency calls when failures hit during production runs.

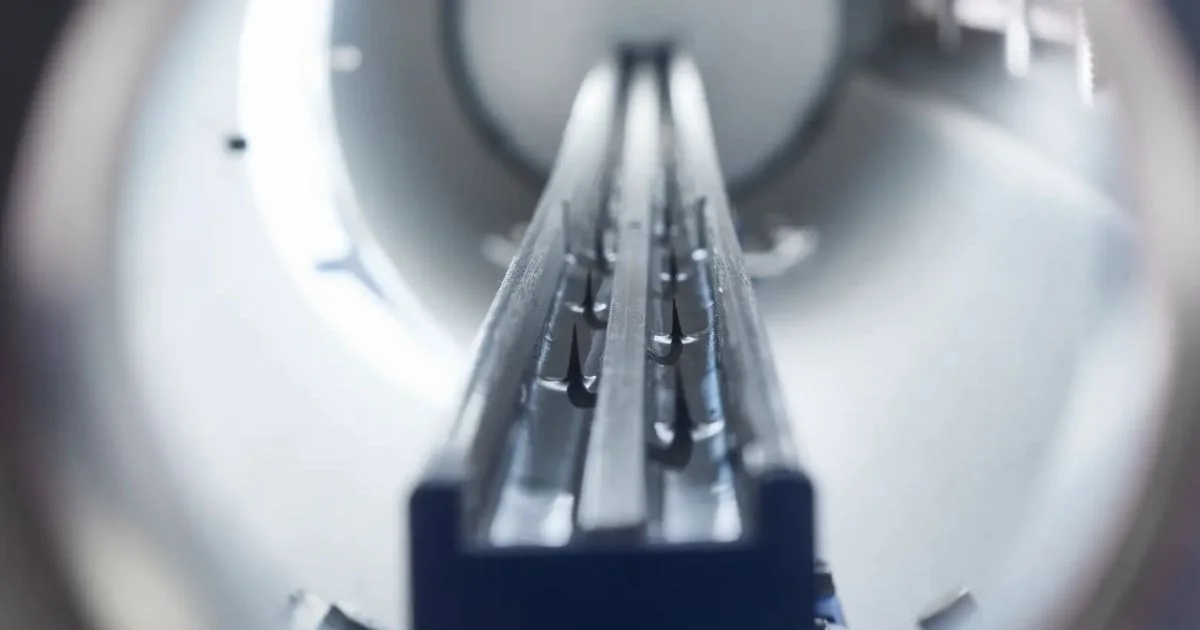

At Air Force 1, we manufacture only direct drive blowers for our blow off systems. The motor shaft connects directly to the impeller. No belts, no pulleys, no tensioners.

This decision costs us sales. Customers see higher initial prices in our quotes than in belt-driven alternatives. They don't always understand why until they've run the equipment for a few years without maintenance headaches.

We're fine with that trade off.

The Belt Problem Nobody Talks About

Walk through any plant running belt-driven blowers and you'll hear it. That slight squeal from a belt that's starting to slip. The vibration that's just a bit worse than it used to be. Those early warning signs that maintenance teams learn to recognize before the real breakdown happens.

Belts wear out through normal operation. Rubber deteriorates from heat and stress. Even when properly tensioned, they gradually lose grip. This creates efficiency losses long before the belt fails. Your blower runs harder to deliver the same airflow, burning more electricity to compensate for slipping power transfer.

Alignment compounds the problem. When pulleys aren't perfectly aligned, belts wear unevenly. Belts start tracking to one side and develop hot spots that indicate impending failure. The bearing loads increase because components fight each other instead of working together. What starts as minor misalignment accelerates into multiple failures across the system.

Temperature swings make everything worse. Belts expand and contract with ambient conditions. Summer heat loosens them. Winter cold makes them brittle. Facilities without climate control see dramatic changes in belt performance across seasons, requiring constant adjustment to maintain proper operation.

The maintenance burden never ends. Even facilities with excellent preventive programs spend significant labor on belt systems. Maintenance teams check tension, verify alignment, and inspect for wear before eventually replacing the belt entirely. Those tasks pull skilled technicians away from work that actually improves production instead of just maintaining baseline operation.

The recurring equipment breakdowns and rising blower maintenance costs signal it's time to rethink your approach entirely.

Why Direct Drive Changes Everything

Direct drive blowers eliminate the entire belt maintenance cycle. The motor and impeller share the same shaft. Power transfers directly without intermediate components. This simple design removes multiple failure points that plague belt-driven alternatives.

Consistent performance comes standard. Direct connection means the impeller always turns at motor speed. No slippage reduces efficiency. No gradual degradation requires compensation. The system delivers rated airflow from installation through years of operation without the performance decay belt systems experience.

Industrial blower efficiency improves across the board. Power that would be lost through belt friction goes directly to moving air. The U.S. Department of Energy notes that V-belt efficiency can deteriorate by as much as 5% over time due to slippage. Direct drive eliminates mechanical losses that belt systems can't avoid.

Maintenance schedules simplify dramatically. Direct drive systems need basic motor maintenance on manufacturer intervals. That's it. Your maintenance team skips the weekly tension checks, monthly alignments, and emergency belt swaps that eat up productive time. Your team focuses on actual improvements rather than constant maintenance of wearing parts.

Space requirements often decrease with direct drive designs. Without pulleys and belts requiring clearance for service access, the entire assembly can be more compact. This matters in retrofits where existing equipment locations have limited room for upgrades.

Temperature stability improves operation. Motors and bearings are designed to handle their operating temperatures. Belts introduce another thermal variable that affects performance. Removing belts means one less component fighting against ambient conditions and creating inconsistent behavior.

What This Means for Blow Off System Blowers

Air knife systems demand consistent airflow to maintain performance. When blowers deliver uneven pressure, air knives can't create the uniform sheet of high-velocity air needed for effective drying or cleaning. Belt slippage during production creates exactly that problem.

We've seen facilities where belt-driven blowers couldn't keep up during peak production. Line speeds dropped or parts came through wet because the blow off system couldn't maintain rated capacity. The belts were slipping under load, and nobody realized it until quality problems surfaced downstream.

Direct drive eliminates that variability. The airflow you get at installation is the airflow you get five years later. Parts dry consistently. Quality stays predictable. Production scheduling doesn't need to account for gradual system degradation.

Shot removal applications show the difference clearly. When you're blasting residual media from castings or machined parts, inconsistent air velocity means incomplete cleaning. Quality suffers because contaminated parts slip through inspection or get caught at the last minute. Direct drive maintains the velocity needed to remove embedded particles reliably, batch after batch.

Static control systems integrated with air knives face similar demands. The ionizing bars need steady airflow to deliver ions effectively across the surface. Belt slippage creates dead zones where static charges persist, attracting contaminants back to supposedly clean parts. Consistent blower performance prevents those failures.

Heated blow off systems combine airflow with temperature control. When belt-driven blowers lose efficiency, the air volume drops while heating elements maintain temperature. This creates hot spots instead of uniform drying. Direct drive keeps the airflow stable so heating works as designed.

The Reliability Calculation

Belt driven blower problems cost more than replacement parts. Every breakdown stops production. Rush orders for overnight belt delivery cut into budgets. Service calls during off-shifts trigger premium labor rates. Those indirect costs dwarf the price of belts themselves.

Unplanned downtime hits hardest. When production schedules assume equipment availability, unexpected failures create chaos. Orders get delayed. Customers receive late shipments. Your reputation takes hits that no amount of apologizing repairs.

Direct drive systems reduce all those burdens. Fewer service events mean simpler scheduling. You'll carry fewer spare parts and spend less time training maintenance teams on belt systems. The reliability translates to predictable operating costs that stay consistent year after year.

OSHA guidelines emphasize routine preventive maintenance to prevent equipment failures. Direct drive delivers better long-term value by reducing maintenance demands while improving workplace safety.

Planned maintenance creates different problems. Taking equipment offline for belt service means coordinating with production schedules, finding coverage for technicians, and hoping nothing else breaks while you've got systems apart. Even routine maintenance becomes a production planning challenge.

Blower maintenance costs extend beyond direct labor and parts. Training requirements increase when systems have more service points. Documentation becomes more complex. Spare parts inventory expands. The total cost of ownership climbs steadily.

Understanding how hidden maintenance expenses accumulate over time helps explain why direct drive delivers better long-term value despite higher upfront investment.

Why We Made This Choice

We could offer belt-driven options. Other manufacturers do. Some customers even ask about them because that's what they're familiar with.

But we've installed systems in enough facilities to see the pattern. Belt-driven blowers cause more service calls. They generate more emergency situations. Customers end up frustrated with equipment that should just work but doesn't.

Making direct drive standard protects our customers from problems they don't need. It also protects our reputation. When systems run reliably without constant maintenance, everyone benefits. Your team stays productive. Your facility avoids costly downtime. We avoid service calls for preventable failures.

This approach costs us some potential sales. Customers comparing quotes see higher initial prices on direct drive equipment. They don't always understand why until they've experienced years of operation without belt problems.

We accept that trade off. Short-term price sensitivity matters less than long-term customer satisfaction. Facilities that choose Air Force 1 get equipment that keeps running. That's worth more than winning on initial cost alone.

The performance difference shows up quickly. Facilities switching from belt-driven systems report immediate improvements in reliability and consistency.

Production teams stop worrying about blow off equipment because it just works. Maintenance teams redirect time toward activities that improve operations instead of constantly fixing worn belts.

The complete comparison between direct drive and belt drive technology reveals why this design choice affects every aspect of blow off system blowers performance.

Making the Right Choice for Your Facility

If you're evaluating blow off system blowers, the belt versus direct drive decision affects your operation for years. Lower initial cost on belt-driven systems gets offset by higher maintenance expenses, unplanned downtime, and gradual performance degradation.

Direct drive blowers deliver consistent operation without the maintenance burden. Air knife systems maintain uniform performance. Production scheduling stays predictable. Your team focuses on making products instead of fixing equipment.

We manufacture direct drive blowers exclusively because that's what performs best in real manufacturing environments. After thousands of installations, the data is clear. Direct drive prevents problems rather than creating them.

Your blow off system should support production, not interrupt it. Direct drive makes that possible through simple, reliable design that eliminates predictable failure points. That's why it's the only option we offer.

Ready to eliminate belt maintenance from your operation? Contact our team to discuss how direct drive technology can improve your blow off system reliability and reduce your long-term maintenance costs.