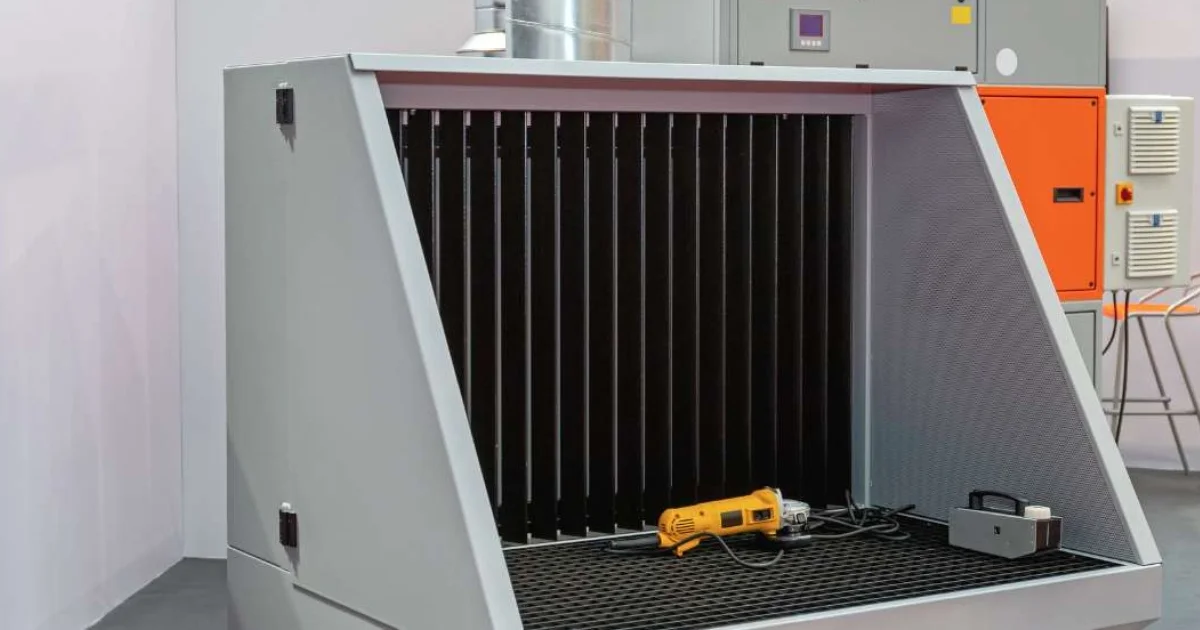

Down draft tables are by far one of the most useful modern-day iterations of workbenches. They're a highly desirable piece of equipment for every industrial worker. Generally, if your work causes excessive dust, shavings, chips, or other potential contaminants, a down draft table is a must-have.

A down draft table helps mitigate airborne particles by passing them through a filtration system before returning clean, fresh air back into the room.

Air Force 1 (AF1) Blow-Off Systems offers some of the most cutting-edge blow-off technology, including patented down draft tables for several industrial applications. Today, we’ll be discussing everything related to down draft tables, and whether or not they’re a suitable solution for your workforce.

But First...What are Down Draft Tables For?

Simply put – down draft tables are used as working tables. When you're ready to work on your project, you'll gather your tools and materials and head to your down draft table.

Unlike a standard workbench, down draft tables offer a significant advantage. These tables have a built-in airflow system that creates a downward suction when activated. This airflow pulls dust, shavings, and other debris away from your workspace, preventing them from getting into your eyes, nose, or lungs.

Not only does this protect your health, but it also keeps your work area clean and provides clear visibility for precise work.

Are Down Draft Tables Effective?

Generally, this depends on the application of the equipment. Down draft tables work in a lot of versatile cases. Whether they'll work for you depends on two primary things: do you perform a task that will benefit from using a down draft table? And did you pick a suitable down draft table?

Here are some examples of applications that can benefit from a down draft table:

Woodworking: Utilized for sanding, grinding, and carving wood, down draft tables capture sawdust, woodships, and other fine particles – keeping your work area clean while reducing the risk of respiratory problems.

Metalworking: Down draft tables can be ideal for tasks such as welding, grinding, and cutting metal. They help to contain metal shavings, sparks, and fumes, protecting workers and maintaining a clean workplace.

Automotive: When it comes to tasks like sanding car parts, grinding, or preparing surfaces for painting, down draft tables efficiently capture dust and debris, ensuring a clean surface for improved finishing.

Stone and Marble Working: Down draft tables are used when cutting or polishing stone for several applications, such as marble and granite, and can be used to capture dust and particles – subsequently preventing them from scattering while also improving visibility in the workstation.

Composite Materials: When working with materials like fiberglass, carbon fiber, or other composite materials, down draft tables capture harmful dust and particles generated during the grinding, sanding, and cutting process.

Electronics: When soldering or working on delicate electronic components, down draft tables can help to remove fumes and small debris, ensuring there is no contamination as well as a clean working environment.

Painting and Finishing: Down draft tables are used in paint preparation areas to capture overspray, dust, and other particles, ensuring a smooth finish and reducing the risk of defects.

Laboratory Work: In labs, down draft tables can be used for chemical mixing or material testing, where it's essential to control airborne particles and maintain a clean environment.

When it comes to choosing your down draft table, you should consider a few things:

Size

Power

Filtration

Material

Noise

Portability

Durability

Application

Maintenance

Budget

Looking for a down draft table that is suited to your unique needs? Contact AF1 today. We are a leading force in providing industrial blow-off systems and can match you to the right equipment for the job.

The airflow of a down draft table involves the volume of air it can process while you’re working, directing it through its built-in filtration system. The overall effectiveness of this airflow depends entirely on the make and model that you choose, along with any available specifications.

To make sure you’re choosing the right table, there are a few considerations to bear in mind:

The intensity of the work.

The materials being used.

The minimum particle size.

By keeping these aspects in mind, you can make a better, more informed decision. If you’re interested in exploring a selection of down draft table technology, get a quote from AF1 today.

Examples of Down Draft Table Utilization

Now that we’ve discussed a few industrial applications for down draft tables, we’ll take you through what some of those practical uses could look like. Of course, we won’t have time to take you through every single one, but we’ll provide you with some real-world examples.

Down Draft Tables in Woodworking

Woodworking produces a lot of fine dust and small particles that can not only obscure your vision, but could be a health and safety issue if not properly managed. Down draft tables can be used during sanding, creating a high volume of fine wood dust.

This wood processing causes tiny particles of wood dust to become airborne, which can subsequently be breathed in by workers. Generally, a person’s upper respiratory system can filter out most larger particles, but smaller particles can travel deep into the lungs, causing potential damage and scarring to the lung tissue. This contributes to health complications over time.

Also, the presence of glues, resins, formaldehyde and other wood treatment chemicals in some products can increase potential health risks.

With a down draft table, the fine dust and wood chippings are then directed through an additional dust extraction filter unit, which effectively removes these particles from the work environment. This process reduces the risk of injury and minimizes exposure to wood dust.

Down Draft Tables in Metalworking Shops

With the ability to both capture particles and remove fumes, a downdraft table is an asset to any welding setup.

Welding fumes are a well-known carcinogen and can pose potentially serious health risks to workers. When it comes to metalworking in general, these tables can be used for grinding, as they can easily collect any shavings from the process, limiting the possibility for injury.

If the down draft table is equipped with a solid particle filter, it effectively removes these particles from the environment. This added protection reduces the risk of metal chips embedding in the skin or being inhaled, enhancing the safety of those working at the table.

Should You Buy a Down Draft Table for Your Workshop?

It’s important to know that down draft tables aren’t just for big manufacturers. They can be suitable for small businesses or even personal use (depending on the application). Everyone can benefit from having a healthier, safer environment in their working space, whether you’re working for a big manufacturing company or just working on a new hobby project.

Depending on what you need it for, there are even portable down draft tables available on the market that can be transported if required. But these aren’t really for industrial use – these are more appropriate for those who want to utilize it for hobby projects.

Your down draft table is awaiting you – you just need to find the right one. And luckily for you, AF1 can help match you to the right one. Our professional staff can provide you with any additional information you need to make sure you have the right down draft table for the job. We can also arrange for the installation of the equipment to ensure your business doesn’t face too much downtime.

Our products are well known for suiting the needs of several industries, and we pride ourselves on our products’ safety and overall quality, ensuring there’s no compromises during the manufacturing process.

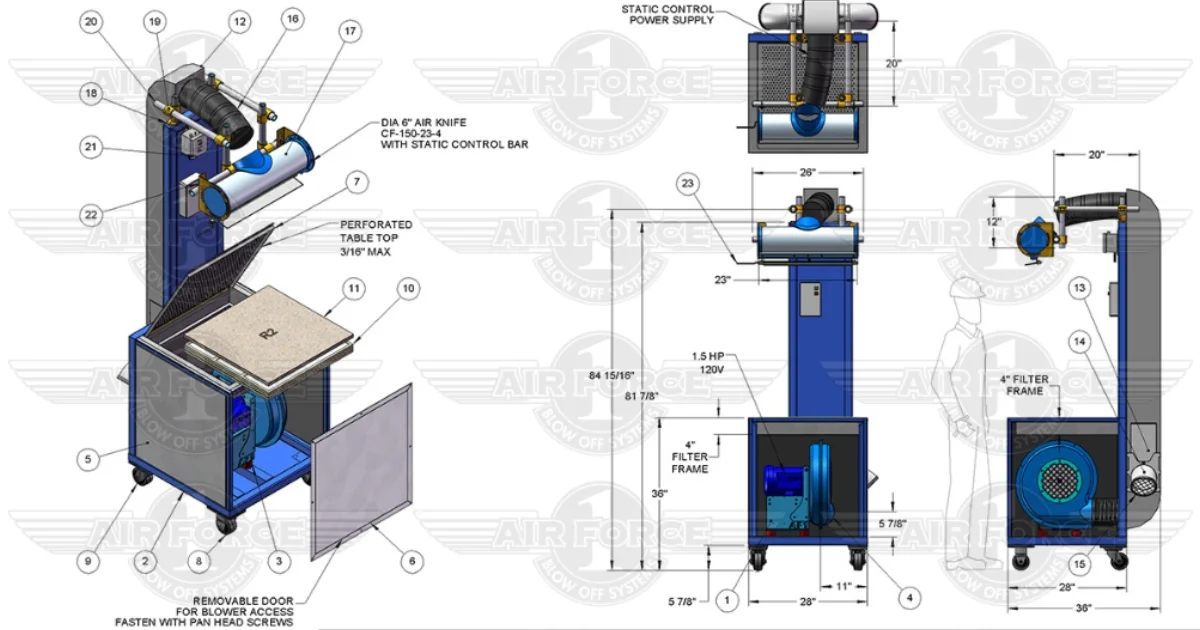

AF1 recognizes that your processes are distinct, and thus require customized solutions. Our engineering team utilizes advanced tools like AutoCAD and SolidWorks CAD programs, allowing us to collaborate closely with you throughout the entire design phase. From concept sketches to markup and approval drawings, and finally to assembly and as-built drawings, we ensure that your system is tailored to meet your exact requirements before construction starts.