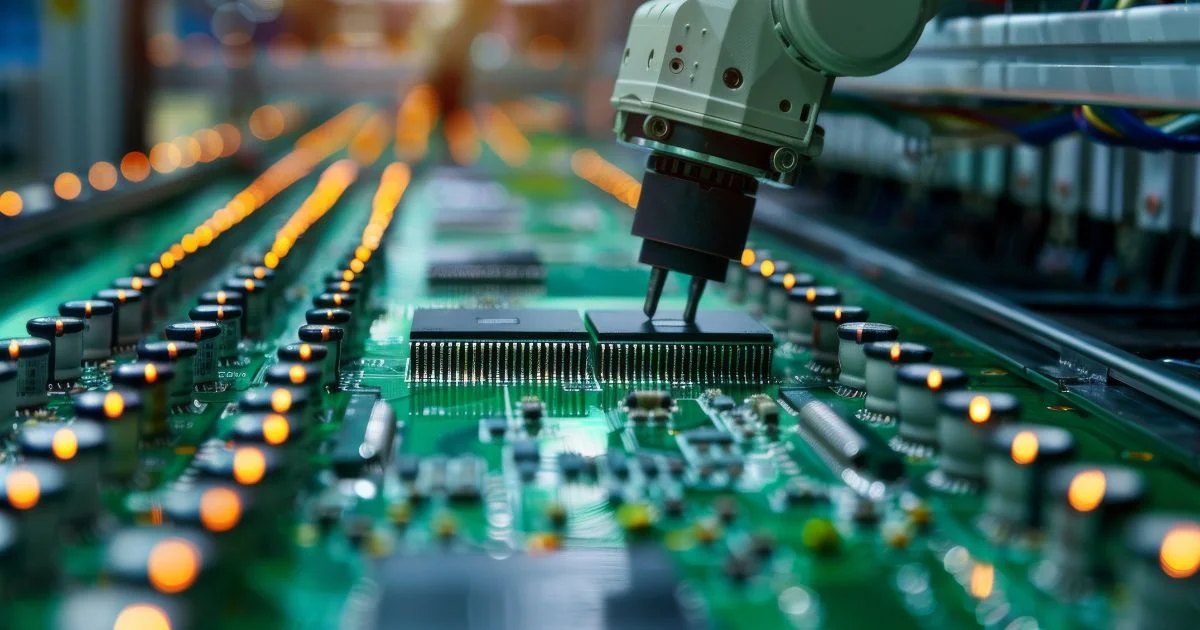

Your production line just rejected another batch of circuit boards. Tiny particles that won't show up until testing have caused shorts. Static electricity built up on plastic parts and pulled in more dust.

These problems cost electronics makers millions in rework and warranty claims. Most contamination happens during final assembly. Products are nearly done. A single speck of dust or static discharge can destroy parts worth hundreds of dollars.

Air knives for electronics manufacturing solve these exact problems. These tools create a sheet of high-speed air. They remove dirt without touching parts. Built-in static control stops harmful electrical charges. You'll learn how these systems prevent contamination and protect your investment.

The Hidden Contamination Problem in Electronics

Electronics manufacturing faces contamination challenges that other industries don't have. Parts keep getting smaller. Tolerances get tighter. What used to be harmless dust now causes big failures.

Tiny particles create shorts between traces on circuit boards. Good systems must remove particles as small as 0.3 microns to prevent failures. Standard cleaning methods can't reach this level consistently.

Throughout our experience, we've seen how contamination sneaks into production. Workers wearing synthetic clothes generate static charges. These charges attract airborne particles. Cutting and drilling create metal shavings that stick to parts. Even small vibrations shake dust loose onto sensitive surfaces.

The money impact hits multiple areas. Rework costs climb when dirty boards fail testing. Warranty claims spike when products fail months later. Customer confidence drops with each quality issue.

According to electronics manufacturing experts, contamination-related defects cost electronics makers big production losses and energy waste through rework cycles.

When it comes to circuit board contamination control, static electricity creates the biggest challenge. It actively pulls particles toward parts. Once charged, plastic housings and circuit boards become magnets for dust, lint, and metal particles.

Why Static Electricity Destroys Electronic Parts

Static electricity poses two threats to electronics manufacturing. First, it attracts dirt to freshly cleaned surfaces. Second, static discharge can damage or destroy sensitive parts instantly.

Modern semiconductors can be damaged by static charges as low as 10 volts. That's far below what humans can detect. These failures often appear as random problems that are hard to diagnose. This makes static control for electronics absolutely essential for preventing costly failures.

The problem gets worse in dry environments where static builds up more easily. Winter months see big increases in ESD-related failures as humidity drops. Even with antistatic straps and mats, airborne static charges continue affecting production quality.

Traditional compressed air actually makes static worse. It creates friction as air moves through hoses and nozzles. This generates more static charge that defeats the purpose of cleaning. Workers unknowingly create more problems while trying to solve contamination issues.

We've seen facilities where switching from compressed air to properly designed systems dramatically reduced ESD failures. The difference comes from built-in static control that neutralizes charges while removing particles at the same time.

How Air Knife Technology Works in Electronics

Creating laminar flow is what makes air knives so effective. This means smooth, parallel layers of air that remove dirt without turbulence. This controlled airflow prevents particles from scattering and dirtying nearby areas.

Precision matters enormously in electronics work. Circuit boards contain parts at different heights that create areas where particles can hide. Laminar flow reaches these spaces uniformly. It ensures complete cleaning without damaging delicate parts.

Air knives with adjustable gaps let operators fine-tune airflow for different board types. The ability to change air velocity from gentle to aggressive means one system handles multiple product lines effectively. This flexibility reduces equipment costs while improving cleaning consistency.

Air Force 1's air knives can be manufactured in lengths from 6 inches to over 240 inches. This makes them suitable for everything from small prototype boards to large automotive control modules. Custom lengths ensure complete coverage without wasted airflow or energy consumption.

Static Control Integration That Actually Works

The most effective cleaning systems combine air knives with built-in static bars. These specialized ionizing systems neutralize static charges while airflow removes particles. This dual action prevents contamination from returning after cleaning.

Static bars generate positive and negative ions that neutralize surface charges on parts and assemblies. When built into air knives, the ionized air flows directly over products. This ensures complete static neutralization. This approach works far better than separate static control devices positioned elsewhere.

Timing matters critically in managing static buildup. Surface charges can be rebuilt within seconds in low humidity environments. Continuous ionization during airflow maintains neutral surfaces throughout the cleaning process.

Different electronic materials require specific ion concentrations for optimal results. Plastic housings need different treatment than bare circuit boards. Advanced systems adjust ion output automatically based on material type and environmental conditions.

We've seen significant improvements when facilities upgrade from basic ionizers to integrated systems. Electronics manufacturers report substantial reductions in field failures after installing static-controlled air knives on their assembly lines. These investments typically pay back quickly through reduced warranty costs.

Protecting Different Electronic Component Types

Various electronic parts require tailored protection strategies. Surface-mount components need gentle airflow that won't displace parts during cleaning. Through-hole components can handle higher velocities but require complete coverage to reach beneath raised packages.

Flexible circuits present unique challenges because they can move or vibrate under airflow. Too much air velocity causes flutter that prevents effective cleaning. Air knives with precise velocity control maintain just enough force to remove particles without disturbing the flexible substrate.

Large assemblies like automotive control modules contain mixed component types requiring multiple air knife positions. Strategic placement ensures every surface receives appropriate treatment without over-processing any area.

Semiconductor wafers demand the most precise control of any electronic component. Minor airflow disturbances can cause significant yield losses in these high-value processes. Laminar flow air knives suitable for semiconductor applications provide the gentle, controlled cleaning these sensitive products require.

Choosing the Right System for Your Application

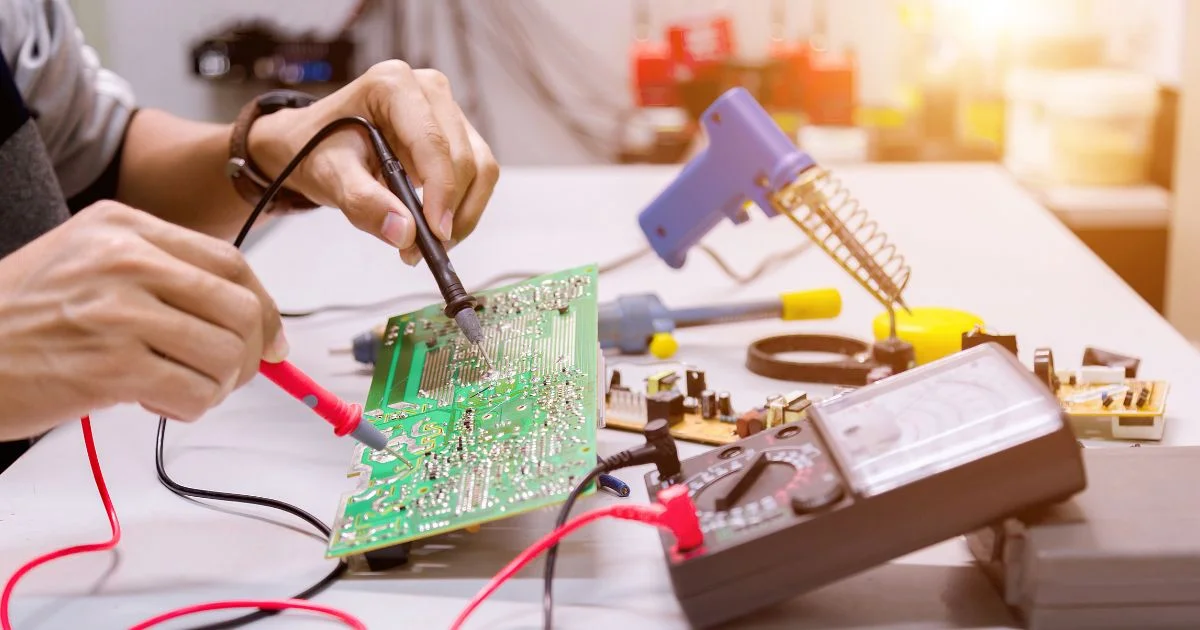

Selecting effective air knife systems starts with understanding your specific contamination challenges. What particle sizes cause failures? Which parts are most sensitive to static discharge? Where does contamination enter your process? These questions drive system design decisions.

Air volume requirements vary significantly between applications. Small circuit boards need less airflow than large automotive modules. Overdesigned systems waste energy while underdesigned systems leave contamination behind. Proper sizing balances effectiveness with operating costs.

Requirements for managing static buildup depend on component sensitivity and environmental conditions. High-volume manufacturing in dry climates needs more aggressive ionization than small-batch production in humid areas.

Proper contamination control in electronics manufacturing significantly reduces defect rates and improves product reliability. This makes the investment in quality air knife systems essential for competitive manufacturing.

At Air Force 1, we analyze your specific application before recommending solutions. Our engineering team uses AutoCAD and SolidWorks to design systems that integrate seamlessly with existing equipment while delivering optimal contamination control for your specific products and processes.

Energy Efficiency and Cost Control

Modern air knife systems deliver big energy savings compared to compressed air alternatives. The U.S. Department of Energy reports that compressed air is one of the most expensive utilities in manufacturing facilities, often accounting for 10-30% of total electrical consumption.

Direct drive blowers used in air knife systems eliminate belt losses and reduce maintenance requirements. The motor shaft connects directly to the impeller for maximum power transfer and minimal energy loss. This design approach delivers better energy efficiency than traditional belt-driven systems.

Variable frequency drives on blower systems allow precise matching of air output to actual cleaning requirements. During lighter production periods, systems automatically reduce power consumption while maintaining cleanliness.

For insights into comprehensive system efficiency, review our detailed analysis in Why You Need a Complete System Approach for Effective Blow-Off.

Installation and Maintenance Considerations

Successful air knife installation requires careful planning of ductwork, electrical connections, and integration with existing production equipment.

Undersized ductwork creates pressure drops that reduce cleaning effectiveness. Oversized systems waste energy and create unnecessary noise.

Preventive maintenance schedules keep air knife systems operating at peak performance. This includes regular filter changes, static bar cleaning, and airflow verification. Well-maintained systems deliver consistent results while minimizing unexpected downtime.

Training operators on proper system use ensures optimal performance and longevity. Simple adjustments like gap settings and air pressure can dramatically affect cleaning results. Operators who understand these relationships maintain better system performance and identify potential issues early.

Smart Solutions for Tomorrow's Manufacturing

Electronics manufacturing continues evolving toward smaller parts and tighter tolerances. This trend makes contamination control even more critical for maintaining product quality and reliability. Air knife technology keeps pace through improved precision and enhanced static control capabilities.

Smart contamination control systems that monitor particle levels and adjust cleaning parameters automatically represent the next advancement. These systems optimize performance while reducing energy consumption and maintenance requirements.

Your electronics manufacturing operation needs contamination control that keeps pace with advancing technology. Properly designed air knife systems with built-in static control protect your investment while improving product quality and reliability.

Ready to eliminate contamination problems that cost time, money, and reputation?

Contact our engineering team to discuss how custom air knife solutions can protect your sensitive electronics throughout manufacturing. We'll analyze your specific challenges and design systems that deliver measurable improvements in quality and productivity.