Cross-contamination is the transfer of unwanted contaminants — such as microorganisms, chemicals, or other particles — from one surface or area to another. To keep things running smoothly and safely (and to stay on the right side of industry regulations), preventing cross-contamination is non-negotiable.

In this post, we explore how Air shower systems help to prevent cross-contamination in a wide range of industrial applications.

How Does Cross-Contamination Happen?

Cross-contamination happens when harmful microorganisms, allergens, or other unwanted substances are unintentionally transferred from one surface or object to another. This can occur in a few different ways.

First, we've got the human element. Even with well-trained personnel and strict protocols, mistakes happen. Improper hygiene practices or mishandling materials can introduce contaminants.

Then, there's the equipment itself. Failure to properly clean and sanitize equipment between production runs can harbor and transfer contaminants. Difficult-to-clean equipment designs, or improper maintenance, can create niches where contaminants accumulate and proliferate. Worn seals, damaged surfaces, or faulty equipment can further increase the risk.

And let's not forget about the environment. Dust, microbes, and other particles can become airborne and settle on surfaces or come into direct contact with the product. HVAC systems, while necessary for climate control, can circulate these contaminants if not properly maintained and equipped with appropriate filtration.

The consequences of cross-contamination can be severe: product recalls, production downtime, and damage to a company’s reputation. In the worst-case scenarios, it can even put consumer health at risk.

Preventing cross-contamination protects your efficiency, your brand image, and most importantly, the people who use your products. And air shower systems play an important part in a comprehensive prevention process.

How Air Showers Help Prevent Cross-Contamination

Air showers are enclosed chambers that use high-velocity jets of clean air to dislodge and remove particles from people and materials before they enter the cleanroom. It’s a bit like a human-sized car wash that uses air instead of soap and water.

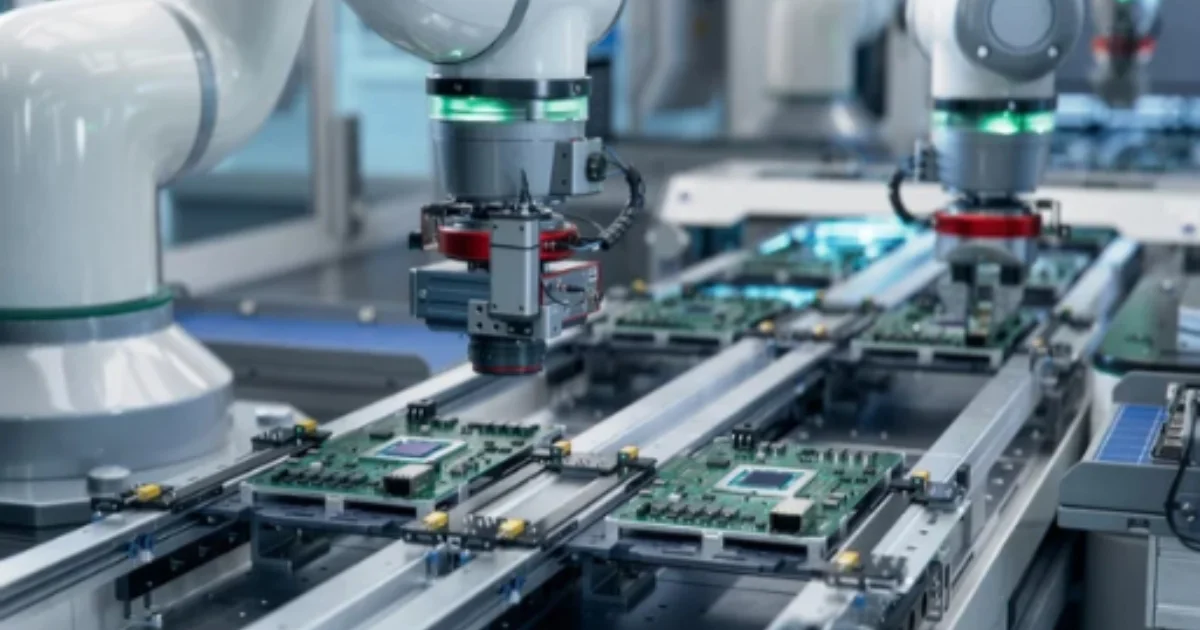

Cleanrooms are strictly controlled environments where the levels of dust, microbes, and other airborne particles are kept extremely low. They are utilized in industries where even microscopic contaminants can readily damage products or cause defects, like pharmaceuticals, biotechnology, and printed circuit board (PCB) manufacturing.

Air showers are, quite literally, the gatekeepers of these cleanrooms. They act as a physical barrier between the pristine cleanroom environment and the not-so-clean outside world, blasting away any contaminants that might be clinging to personnel or equipment.

Not all cleanrooms have air showers, but those with stricter particle control requirements (e.g., ISO Class 5 and lower) are more likely to have them.

How Air Shower Systems Work

When someone enters an air shower, they are enveloped by powerful jets of filtered air from multiple directions and angles. These jets dislodge particles from all surfaces, including clothing, hair, and equipment.

The air used in the shower is not plain, ordinary air. It first passes through High Efficiency Particulate Air (HEPA) filters, which remove a very high percentage of particles, to ensure that the air blasting through the shower won't introduce any new contaminants.

The force of the air creates a swirling motion within the air shower that reaches every nook and cranny – folds in clothing, divots in equipment, and just about every surface where particulate matter could hide. As particles are dislodged, they are sucked away by a powerful filtration system and expelled from the air shower, preventing them from reaching the cleanroom.

To make extra sure that airborne contaminants don't sneak in, many air shower systems have interlocking doors. This prevents both doors from being opened at the same time, maintaining the clean environment inside.

Air Shower Components

Now, let's pop the hood and see what's going on inside these air showers. A few key components work together to make the whole system safe and effective.

Blowers and Nozzles

Powerful blowers are the driving force of the air shower. They generate the high-pressure airflow needed to dislodge contaminants and propel that air through the system and out of strategically positioned nozzles.

Speaking of nozzles – air cannon nozzles are strategically positioned in the air shower to direct those high-velocity air jets exactly where they need to go. The angle and placement of these nozzles are critical for ensuring that every surface gets scrubbed clean.

Ductwork

Connecting the blowers, filters, and nozzles is the ductwork. This is the circulatory system of the air shower that ensures a smooth and controlled airflow. Because we don't want to introduce any new contaminants into the mix, the ductwork is typically made of stainless steel or other non-shedding materials.

Air Ionizers

Air ionizers are often incorporated into air showers to neutralize static electricity. Static electricity can attract and hold contaminants, making them difficult to remove. Air ionizers help to combat this, improving the overall effectiveness of the air shower.

Filters

Air showers utilize high-efficiency particulate air (HEPA) filters or ultra-low penetration air (ULPA) filters to remove contaminants from the air. HEPA filters can remove up to 99.97% of particles 0.3 micrometers or larger, while ULPA filters can remove up to 99.9995% of particles 0.12 micrometers or larger.

Closed-Loop Recirculation System

To keep things efficient and cost-effective, many air showers use a closed-loop recirculation system. This means the filtered air gets recycled within the air shower, reducing the need to constantly condition new air.

Benefits of an Air Shower System

Air showers are essential for keeping contaminants out of our cleanrooms, which in turn improves product quality, helps us comply with industry standards, and creates a safer, more efficient production environment.

Reducing Contamination Risk

Air showers are our first line of defense in environments where cleanliness is critical. They act as a barrier between the uncontrolled outside world and the pristine conditions inside our cleanrooms.

Air showers dislodge any clinging contaminants by blasting personnel and materials with high-pressure air jets. These particles are then captured by the filtration system, ensuring they don't make their way into the cleanroom. This significantly reduces the risk of cross-contamination, protecting our sensitive processes and products from potentially harmful particles.

Improving Product Quality

We know that even microscopic contaminants can wreak havoc on product quality, especially in industries with strict quality standards. This is especially true in fields like pharmaceuticals, biotech, and electronics, where even minor defects can lead to expensive product recalls or defects.

Air showers help us maintain the quality and consistency of our products, reducing the likelihood of defects and making our production process more efficient.

Complying with Industry Standards

Many industries operate under strict regulations and standards regarding contamination control. Air showers are a proactive way to meet industry standards and maintain a safe, compliant working environment.

Where We See Air Showers in Action

Air showers are used across various industries to maintain contamination control and ensure product quality. Here are some of the common applications of air showers across different sectors.

Life Sciences

In this field, preventing microbial contamination is important during the manufacture, packaging, and storage of pharmaceuticals, medical devices, and biotechnology products. Air showers help maintain sterile cleanroom environments, protecting these sensitive products and processes from contamination.

Electronics Manufacturing

Air showers are essential for minimizing the tiny particles that can cause defects in electronic components and circuits. They also help control static electricity, which can damage sensitive electronics.

Optics Manufacturing

To produce high-performance optics, it's important to minimize dust, fibers, and residue that can affect optical components. Air showers help achieve the pristine environment necessary for this type of manufacturing.

Pharmaceutical Manufacturing

Air showers are critical in pharmaceutical manufacturing to prevent contamination of medications, ensuring their safety and efficacy.

Automotive Manufacturing

Air showers help achieve high-quality paint finishes and specialized coatings in the automotive industry by minimizing contaminants like dust and overspray.

These are just a few examples, of course. Air shower solutions can be customized to meet the unique needs of different industries and applications. Air Force 1 specializes in providing custom-designed air showers engineered to your needs and industry challenges.

Choosing the Right Air Shower Supplier

When it comes to building an air shower, you want a partner with a proven track record of designing, manufacturing, and installing high-quality systems that meet industry standards. After all, the effectiveness and longevity of your contamination control system depend on it.

Air Force 1 has over 30 years of experience providing custom blow off and air shower solutions. We specialize in engineering systems that tackle specific production challenges and fit seamlessly into existing workflows. Our in-house manufacturing process ensures quality and durability, and our global reach means we can support your needs wherever you are.

At Air Force 1, we provide solutions. Our team of expert engineers will work closely with you to understand your requirements and design a system that works for you. From the initial consultation and design all the way to installation and ongoing maintenance, we're committed to delivering top-quality results.

Air Showers and Contamination Control

Incorporating air showers into your facility can significantly reduce the risk of contamination, improve product quality, and help you comply with industry standards.

Find out how Air Force 1's air shower solutions can benefit your specific application. Contact us today to learn how we can solve your challenges.