The manufacturing sector comes with a slew of issues that require solutions, some complex and others relatively simple. And sometimes, a seemingly common issue requires a multifunctional solution – such as heated blow off systems.

Drying processes are crucial when it comes to ensuring product quality and overall consistency, which is essential to customer satisfaction. Whether you need to remove water after cleaning parts or dry coatings, the effectiveness of these processes can have a huge impact on the final product.

Perhaps one of the most efficient solutions to common drying issues is the use of a heated blow off system. This method combines the power of air with heat, providing a versatile solution to several drying issues.

Luckily for you, Air Force 1 is comprised of professionals in the field who are well-equipped to guide you through this blog on how heated blow off systems solve common drying problems.

Drying Issues and Solutions

Uneven Drying

So, here’s the problem: Uneven drying can cause wet spots or patches, which has the potential to impact the quality and appearance of a manufacturer’s final product. Of course, there are several industries where this can be an issue, which is why we’re using general terminology. However, some examples include food, pharmaceutical, and medical products, which require very high-quality drying. This issue can commonly be caused by inconsistent heat distribution or airflow.

Here’s the solution: Heated blow off systems use uniform heat distribution across the surface, making sure that every part of the product is dried evenly. This combination of both heat and high-velocity air helps evaporate moisture quickly and uniformly.

These are the benefits: The quality of the product is increased while reducing the need for rework, which benefits your bottom line. It also provides higher consistency in the final product. A heated industrial blower is the obvious solution.

Residual Moisture

Here’s another issue: Residual moisture – a sneaky form of condensation or moisture left on parts that can cause corrosion, contamination, or defects in your final product. This is particularly problematic in industries where both precision and cleanliness are critical.

The solution? Heated blow off systems are incredibly effective when it comes to thoroughly evaporating moisture, even in small, tight crevices or in complex geometrics. With the addition of heat, evaporation is accelerated during the drying process, ensuring there’s no moisture left behind.

These are the benefits: With heated blow drying, your products will have enhanced durability and reliability by reducing the chance for contamination or corrosion. This increases the manufacturer’s quality standard, resulting in better more consistent product.

Slow Drying Times

And another problem! Sometimes, drying just takes a long time, which can slow down production lines and reduce the manufacturer’s efficiency. This is particularly challenging in high-volume manufacturing environments, such as automotive manufacturers.

The solution, you may ask? Heated blow off systems accelerate the drying process by utilizing high amounts of air pressure and heat. This takes that pesky issue of time and reduces the amount of time it requires to dry parts, subsequently speed up production.

The benefits: Utilizing a high pressure blower increases throughput, reducing bottlenecks in the production process and overall improving efficiency.

Energy Consumption

Here’s the problem: Traditional drying methods, plainly put, can be really energy intensive, which subsequently increases your operational costs and can impact environmental issues. With the shift in manufacturers aiming to reduce their carbon footprint, this can be a big priority.

Alas, there is a solution: Heated blow off systems are specially designed to be energy efficient. They use targeted heat and air to speed up the drying process, thereby reducing the overall energy consumption compared to other drying methods, such as using infrared dryers (which are often ineffective for the application). AF1 have provided numerous sources of heated blow offs (utilizing electric, gas, and steam as the source). We will work with the customer to ensure what makes the most sense economically and efficiently for the application.

Temperature Sensitivity

Oh no, another problem: Some materials are simply sensitive to high temperatures, which can cause damage or warping to the product to the drying process.

But fear not, the solution! Heated blow off systems offer controlled, timed, and adjustable heat settings to allow manufacturers to tailor the temperature to the specific needs of their product’s material. This ensures safe drying without the risk of compromising the integrity of the product, especially temperature sensitive parts.

Benefits, benefits, benefits: Heated blow off drying methods makes for safe drying of delicate materials, reducing the potential risk of damage whilst maintaining the quality of sensitive components.

Contamination from Drying Equipment

A pretty serious problem: Physical contact with certain drying tools or materials can introduce contaminants, which compromises the cleanliness and quality of the final product – think of using a dirty dish towel to dry your dishes – it’s counterproductive, and gross. Contamination is a particularly high concern in the pharmaceutical industry, for example.

A pretty efficient solution: Heated blow off systems offer a no-contact means of drying, which greatly eliminates the risk of contamination by using drying equipment. The high-velocity filtered air is perfectly designed to remove moisture without touching the surface of the product, meaning there’s no chance of transferring contaminants even accidentally.

And, of course, the benefits: High-quality cleanliness, a reduced risk of contamination, and a big increase in quality standards for sensitive applications – what more could you possibly ask for?

Complex Shapes and Hard-to-Reach Areas

A pretty predicament: Perhaps an issue you wouldn’t think of, but there are many instances where parts can have complex geometrics or simply hard-to-reach areas, making them challenging to thoroughly dry using most traditional drying methods. Crevices and hollows can hold moisture, potentially compromising the integrity of the part.

Perhaps the perfect solution: Luckily, heated blow off systems offer both precision and versatility when it comes to more complex parts, allowing high-velocity, heated air to get into even the most hard-to-reach places for efficient and thorough drying.

And of course, there’s benefits: Heated blow off drying allows for the most thorough drying of all surfaces, regardless of how complex the shape is, greatly improving the overall product quality and increasing production efficiency.

So, what does all this mean at the end of the day?

Heated blow off systems offer a versatile and effective solution to many of the problems present in the manufacturing sectors when it comes down to drying parts and products. With the combination of high-velocity air and heat, these systems offer the most uniform drying and eliminate the potential for contamination, issues with temperature sensitivity, and the like.

Not to mention it’s quick and efficient, which is reason enough to utilize it as your primary drying method.

If you’re finding that drying is compromising your products, consider utilizing a heated blow off system to enhance your operations and maintain the quality of your products.

Air Force 1 Blow Off Systems Inc., a leading expert offering tangible solutions

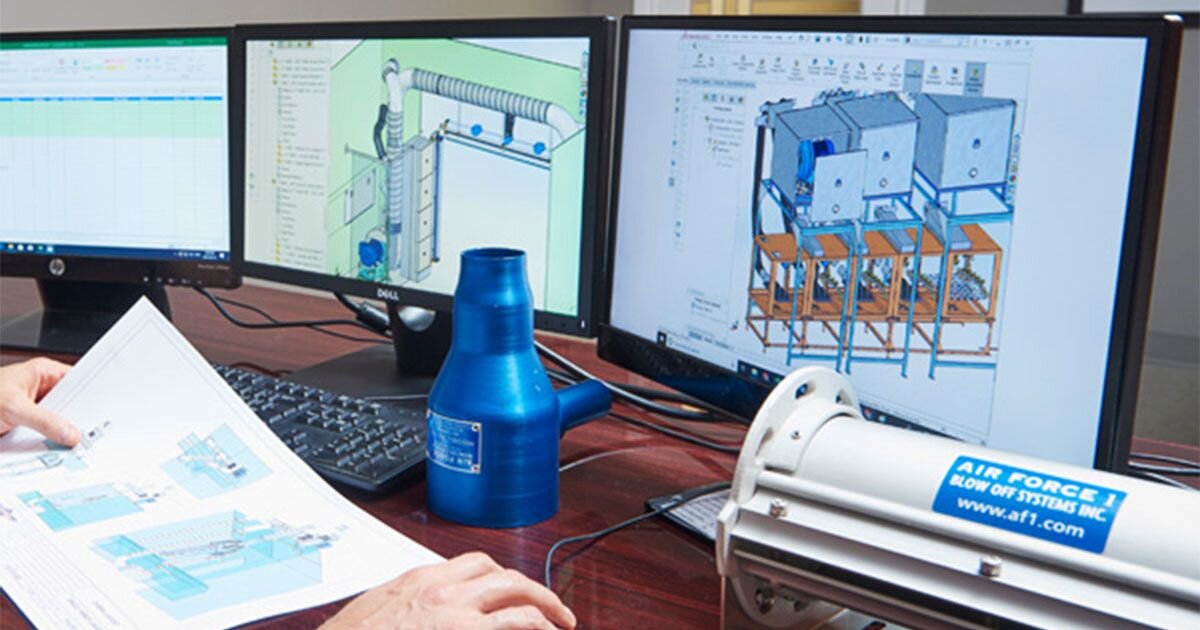

Air Force 1 has been in business since 1990, offering several solutions to manufacturers across a myriad of industries. Our primary focus is designing and manufacturing blower-generated blow off systems that function in industrial, manufacturing, and assembly applications. This also includes the food and beverage industry, defense and packaging industry, too. Our products are world class and designed to remove barriers and efficiently provide the solutions for your business.

We don’t just offer heated blow off systems, either, we have several areas of expertise:

Direct Drive Blowers

Static Control

Drying Systems

Neutralizing

Cooling Stations

Air Seals

Coatings Control

Blower Sound Control Enclosures

Bottle Drying

Liquid Removal

Shot Blast Media Cleaning

Feather Dusters

Heated Blow Off

Where can our products be utilized?

Our products have several applications, and realistically, we could dedicate several blogs and comprehensive articles exploring that subject alone. However, here are just some of the industries and potential applications of our world-class products:

Automotive Industry

Drying parts after washing

Removing debris from components

Food and Beverage Industry

Drying bottles and cans before labeling

Removing debris and moisture from packaging

Pharmaceutical Industry

Drying equipment and containers

Removing dust and contaminants

Electronics Industry

Removing dust and particles from circuit boards

Cooling components during manufacturing

Metalworking Industry

Cleaning metal parts post-processing

Removing shot blast media

Textile Industry

Drying fabrics during manufacturing

Removing lint and dust

Printing Industry

Drying inks on printed materials

Removing paper dust

Aerospace Industry

Cleaning and drying aircraft parts

Removing contaminants from precision components

Plastic and Rubber Industry

Cooling and drying molded parts

Removing static and debris from surfaces

Packaging Industry

Drying packaging materials before sealing

Removing debris from packaging lines

Agriculture Industry

Cleaning agricultural machinery

Drying seeds and grains

Whatever your needs may be, Air Force 1 has world-class products geared specifically to you and your needs. A leader in our respective field, we offer you tailored solutions to help improve your business and keep things rolling properly. Air Force 1 is comprised of a dedicated collective of talented employees devoted to making sure you’re satisfied. For more information, please see our contact page. We also have a quote request form available on our website.