That quality issue that won't go away? Those unexpected jumps in your energy bills? The slowdowns that keep happening in your production? There's a likely cause you've been overlooking – your blow off system.

Most factory engineers know their machines well, but many pay less attention to how air moves in their plants. Airflow in blow off applications brings together physics and practical engineering, yet few people give it the attention it deserves.

A poorly designed blow off system doesn't just waste air – it works against what you're trying to do. When high-pressure air hits a surface without proper direction, it often just moves dirt from one spot to another instead of removing it. At the same time, your compressors work overtime, using extra electricity to make up for an inefficient system – driving up costs and reducing compressed air efficiency.

Successful manufacturers recognize the value of optimizing existing systems. Focusing on the fundamentals of air management can lead to targeted improvements that boost efficiency without necessarily requiring major capital investments. The results often include significant energy savings, improved product quality, and increased throughput.

Laminar vs. Turbulent Flow: What's the Difference?

When setting up a blow off system, you need to choose: Do you want smooth, even airflow (laminar) or powerful, mixing airflow (turbulent)? This choice matters for drying, cleaning, or cooling your products.

Laminar Flow: For Precision Work

Think about pouring honey slowly from a spoon – it flows in one smooth stream. That's how laminar airflow works. The air moves in straight lines without much mixing.

Laminar flow works best when you need:

Gentle treatment for delicate products like electronics

Even drying with no streaks on flat surfaces

Precise control of light dust or particles

The same results every time across many products

Turbulent Flow: For Tough Cleaning Jobs

Now picture stirring honey quickly – creating swirls and mixing patterns. That's turbulent flow, where air moves in random directions and mixes a lot.

Turbulent flow is better when you need to:

Remove stubborn dirt and residue

Clean odd-shaped items with corners and recesses

Cool items faster

Move heavier dirt and particles

Hardware Options: Nozzles and Air Knives

To use airflow in blow off applications effectively, partnering with providers of high-quality equipment, such as specialized nozzles and air knives, is essential.

Beyond Basic Nozzles: Features That Matter

Basic nozzles don't cut it anymore. Today's engineered nozzles work much better. Here's what makes good nozzles different:

Amplification ratio - Good nozzles pull in extra air from around them, giving you up to 25 times more output

Material choice - Stainless steel works for food plants, while special plastics resist chemicals

Internal shape - How air flows inside affect how well the nozzle works

Proper mounting - Even great nozzles fail if they're not positioned correctly

Many factories unknowingly waste air and energy by using high-pressure nozzles. Open blow off systems can consume up to 30% of a facility’s total energy, making air knives & engineered nozzles critical for efficiency.

Air Knife Tips: Solving Common Problems

Air knives make sheets of air for cleaning conveyor belts, flat materials, and large surfaces.

From hundreds of air knife installations, here's what works best:

Air chamber design beats high pressure - Well-designed chambers that spread air evenly work better than just turning up the pressure

Keep the gap even - Small changes in the opening size cause big problems

Position matters - Each job needs specific distance and angle settings

Clean, dry air works best - Using filters and sometimes air dryers prevent many problems

Common Mistakes in Blow Off Applications and How to Fix Them

Recognizing these common errors can significantly improve your airflow system performance:

Mistake #1: Relying Only on Pressure

Problem: When drying results are poor, many operators simply increase air pressure. This wastes energy without fixing the real issue.

Fix: Focus on proper airflow and direction instead of just pressure. Systems with lower pressure but better air delivery clean more effectively while using less energy.

Mistake #2: Using Generic Nozzle Layouts

Problem: Standard nozzle arrangements that don't match your specific products create uneven results and waste air.

Fix: Study your product's shape before designing your system. Placing nozzles to target specific areas works better and uses less compressed air.

Mistake #3: Ignoring Air Quality

Problem: Even well-designed systems perform poorly when air contains moisture, oil, or particles.

Fix: Install proper filters and air dryers. Clean air improves system effectiveness, prevents product contamination, and extends equipment life.

Mistake #4: Overlooking Factory Conditions

Problem: Surrounding temperature, humidity, and nearby equipment affect how well your blow off system works.

Fix: Consider your workspace when planning your system. Areas with high humidity need additional treatment, while spaces with natural airflow may

require protective barriers.

Mistake #5: Insufficient Operator Training

Problem: Good systems often fail when operators make improper adjustments or don't follow procedures.

Fix: Develop clear instructions and train your team thoroughly. Document the optimal settings and explain why they shouldn't be changed without proper assessment.

Making It Work in Your Factory

Moving from ideas to action requires a practical approach. Here's how to set up successful airflow blow off systems in your plant:

1. Start with a Good Assessment

Before changing anything, measure these key factors:

Current performance - How well does your cleaning/drying work now?

Air consumption - Measure actual SCFM usage, not just pressure settings

Process requirements - Identify what your minimum performance needs are

Energy costs - Figure out what compressed air costs you per SCFM

These numbers show where you're starting from and help you track improvements.

2. Design for Your Specific Needs

Good airflow systems must be matched to your exact situation:

Product characteristics - Size, shape, material, and sensitivity

Factory environment - Temperature, humidity, and nearby processes

Line configuration - Speed, direction, and space constraints

Contaminant properties - Particle size, how they stick, what they're made of

One-size-fits-all solutions rarely work well. Many plants waste money on generic systems that don't solve their specific problems.

3. Test Before Going All In

Unless your needs are very simple, testing on a small scale helps a lot:

Start with just one station or line

Collect performance data during actual production

Make adjustments based on what you learn

Document improvements before expanding

This approach reduces risk and often reveals opportunities for improvement that weren't obvious at first.

Energy Efficiency Benefits

Good airflow in blow off applications helps you save money in two ways: lower energy use and less maintenance, ensuring greater compressed air efficiency.

Reducing Power Use

Good airflow in blow off applications helps you save money in two ways: lower energy use and less maintenance. Both directly affect your operating costs.

Lowering Maintenance Needs

Maintenance costs often get overlooked when planning blow off systems. Manufacturers find that their maintenance schedule changes dramatically, from having to replace wiper pads daily to just quarterly inspections and annual filter changes.

When calculating potential savings, be sure to consider:

Reduced power consumption

Fewer replacement parts

Less labor time spent on maintenance

Less production downtime

Fewer quality problems that need fixing

Many manufacturers find their airflow improvements pay for themselves within 6-12 months through energy savings alone.

What's Coming Next in Airflow Technology

The field of airflow in blow off applications keeps advancing. Here are trends shaping the future:

New Technologies to Watch

Digital monitoring - Real-time data on performance and efficiency

Smart control systems - Automatically adjusting airflow based on product type or line speed

Energy recovery - Capturing and reusing energy that would otherwise be wasted

Combined technologies - Mixing compressed air with other methods like ionization

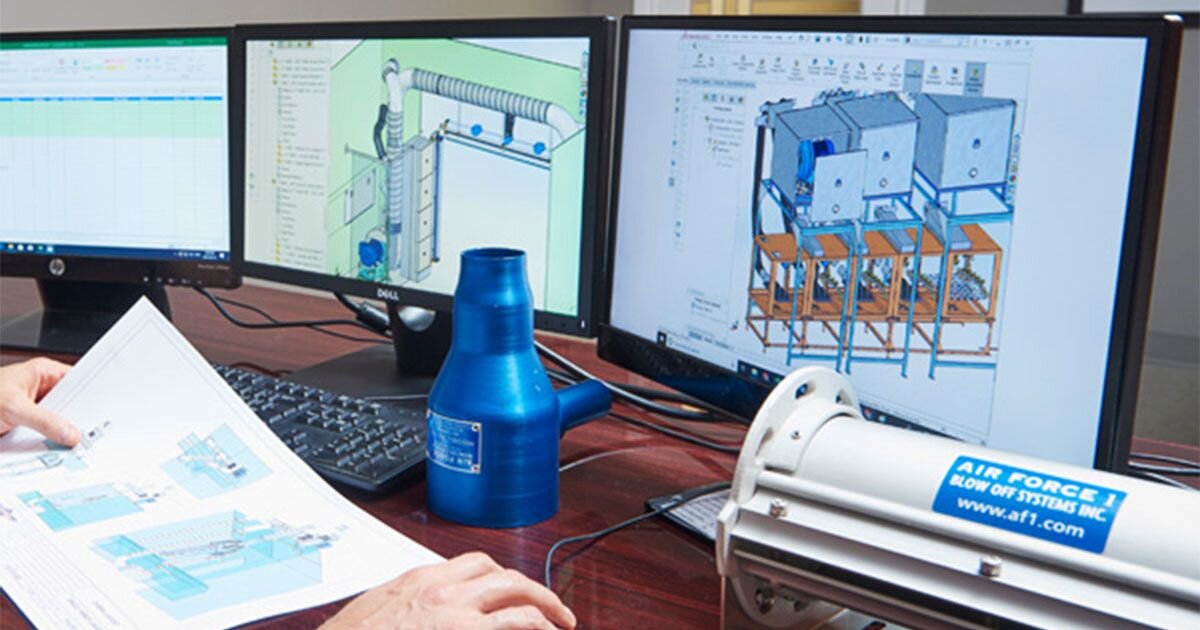

Computer simulation - Using advanced software to design systems before installation

Early adopters of these technologies are gaining significant advantages in performance, compressed air efficiency, and sustainability – key factors for energy-efficient blow off systems.

Why Optimized Airflow Matters to Your Bottom Line

Understanding airflow in blow off applications isn't just a technical topic – it's a business opportunity. Well-designed systems deliver multiple benefits that directly impact your profitability:

Lower energy costs through more efficient compressed air usage

Better product quality and consistency

Faster production without buying additional equipment

Reduced environmental impact

Lower maintenance costs and longer equipment life

These benefits add up over time, often delivering returns far beyond the initial investment.

Ready to improve your production efficiency? Contact our team today for an airflow assessment and discover solutions tailored to your specific manufacturing challenges.